Describtion

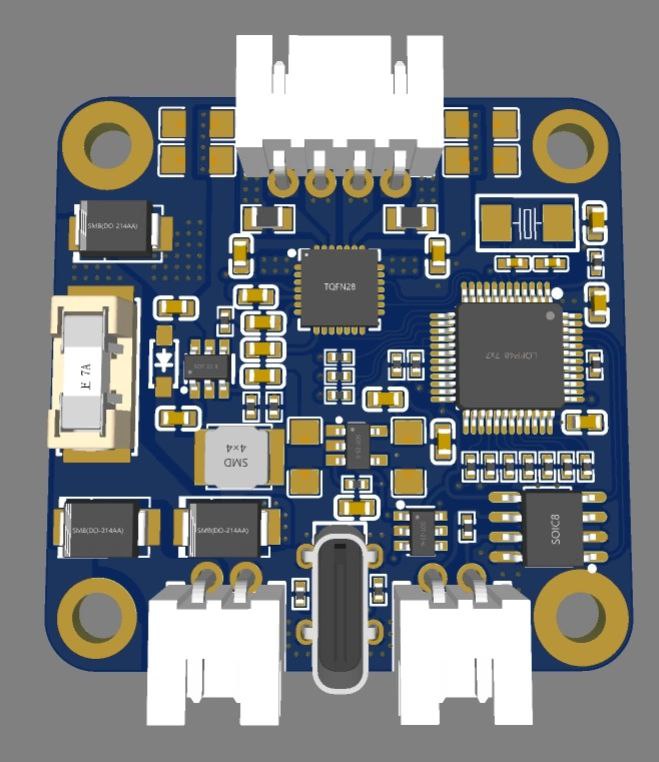

Compact high-precision closed-loop stepper motor driver for NEMA17

Goal

The goal is to develop a closed-loop motor driver with current and position control for precise positioning of moving elements, such as a 3D printer head, at a reasonable price point.

Features

- TMC2209 stepper motor driver with step loss detection, current regulation, step division of up to 1/256, and additional features that reduce idle power consumption. The TMC2209 is a high-quality and efficient driver chip that provides precise and reliable motor control.

- High-precision 14-bit absolute magnetic encoder for detecting missed steps and determining the absolute position of the motor shaft within a range of 0-360 degrees. The encoder provides accurate and reliable position feedback, which is critical for precise positioning of moving elements.

- ARM Cortex M4+ controller that provides calibration and support for 4 control modes, including classic STEP/DIR, I2C, UART, and CAN. The controller is a powerful and flexible microcontroller that can handle various control tasks.

- Power supply with a wide input voltage range of 6-24VDC and reverse polarity protection. The power supply is designed to be flexible and robust, capable of handling different power requirements and protecting the system from power surges and other hazards.

- DCDC converter for MCU powering to reduce power consumption. The inductive converter provides efficient and reliable power conversion, which is critical for minimizing power consumption and improving the overall efficiency of the system.

- Various control options, including current control with programmable current decay mode, position control with support for various feedback devices, and speed control. These control options provide flexibility and versatility for different applications and control requirements.

Challenges

- The driver should be designed to address the shortcomings of existing solutions, including driver overheating, high cost, lack of required features, and large size.

- The custom PCB and enclosure, along with the high-quality driver chip and heatsink, should be designed to improve heat dissipation and reduce overheating.

- The control algorithms should be optimized for different operating modes and tasks, to improve the overall performance of the system.

Innovations

- The resulting driver is the most compact, efficient, and cost-effective solution, with the ability to adapt to various control algorithms for different applications.

- The combination of high-quality components, efficient power management, and flexible control options make the driver a reliable and versatile solution for precise motor control.

ToDo list

- Integration with IoT devices: Enable the motor driver to be connected to IoT devices and controlled remotely through the cloud.

- Real-time data visualization: Develop a dashboard to display real-time motor position, velocity, and other metrics to aid in fine-tuning the control algorithms.

- Enhanced safety features: Implement additional safety features, such as overload protection, overvoltage protection, overcurrent protection, and short circuit protection, to prevent damage to the motor and other components.

- Automatic calibration: Implement an automatic calibration routine to optimize the performance of the motor driver for a given application and eliminate the need for manual calibration.